Fasteners and Machining: Improving the Production Process

Navigating the Globe of Fasteners and Machining: Approaches for Accuracy and Speed

In the complex world of fasteners and machining, the pursuit for precision and rate is a continuous obstacle that demands thorough attention to detail and critical planning. From understanding the diverse variety of bolt kinds to selecting optimal products that can stand up to strenuous needs, each step in the process plays an essential role in accomplishing the wanted end result. Accuracy machining techniques better boost the intricacy of this craft, requiring a fragile equilibrium between technological knowledge and cutting-edge methods. As we delve into the strategies that can improve both speed and efficiency in this domain, the interaction in between quality assurance actions and functional quality emerges as a critical prime focus.

Understanding Fastener Types

When choosing bolts for a job, understanding the numerous kinds available is crucial for making certain ideal efficiency and dependability. Bolts are made use of with nuts to hold products with each other, while screws are functional fasteners that can be used with or without a nut, depending on the application. Washers are vital for dispersing the tons of the bolt and avoiding damages to the material being attached.

Choosing the Right Materials

Understanding the value of choosing the ideal materials is critical in making certain the optimal efficiency and integrity of the picked bolt kinds reviewed formerly. When it involves fasteners and machining applications, the material selection plays an essential role in identifying the overall toughness, resilience, corrosion resistance, and compatibility with the intended atmosphere. Various products offer varying residential properties that can dramatically affect the performance of the bolts.

Usual materials used for fasteners include steel, stainless-steel, aluminum, titanium, and brass, each having its distinct strengths and weaknesses. Steel is renowned for its high toughness and toughness, making it ideal for a wide variety of applications. Stainless-steel supplies superb deterioration resistance, perfect for environments prone to moisture and chemicals. Light weight aluminum is lightweight and corrosion-resistant, making it suitable for applications where weight decrease is important. Brass is commonly picked for its visual appeal and outstanding conductivity. Titanium is known for its remarkable strength-to-weight ratio, making it perfect for high-performance applications. Choosing the ideal material involves taking into consideration factors such as toughness requirements, ecological problems, and budget plan restraints to make certain the desired performance and long life of the fasteners.

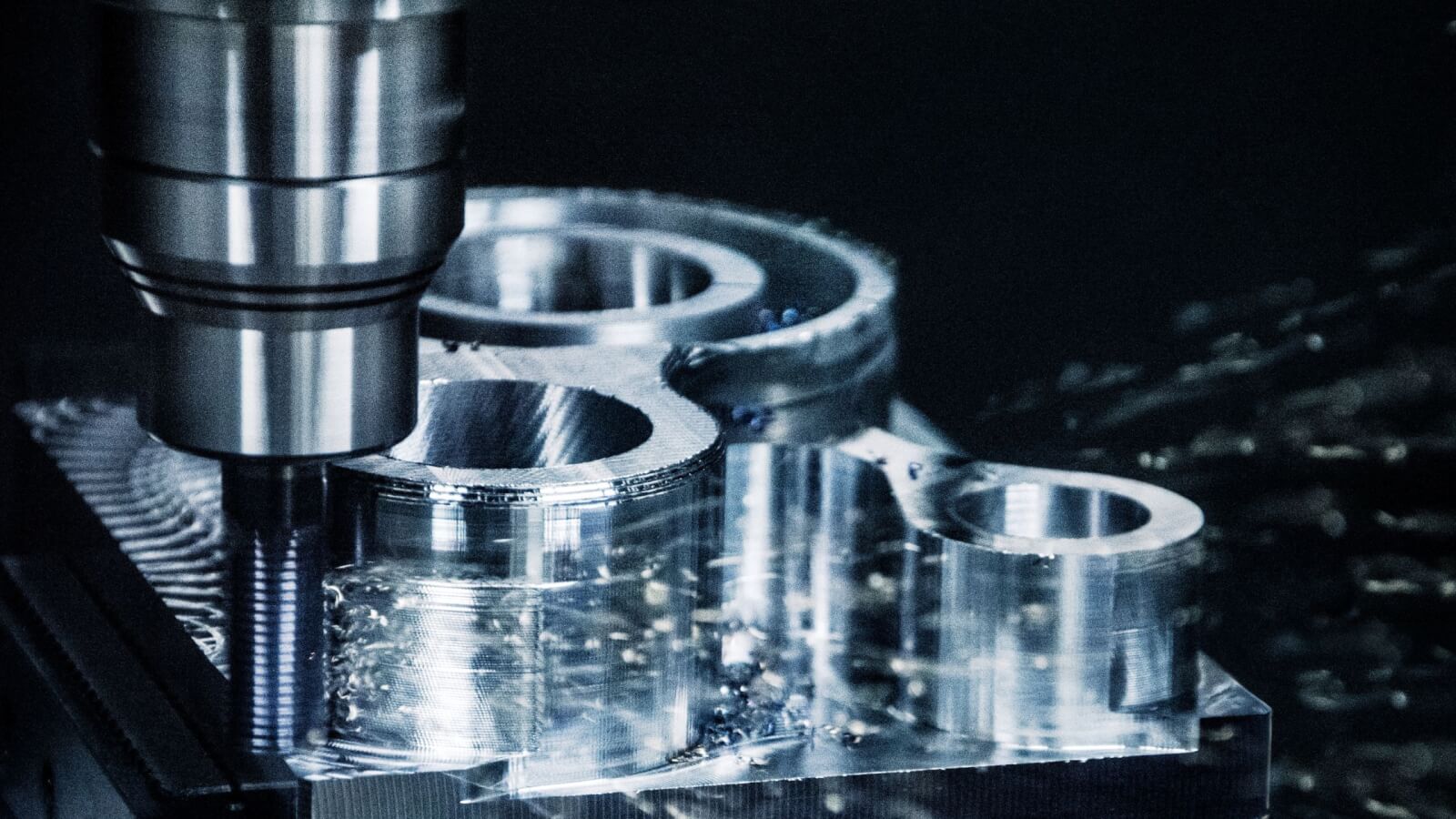

Precision Machining Techniques

Along with CNC machining, other accuracy techniques like grinding, turning, milling, and drilling play essential duties in fastener manufacturing. Grinding helps achieve fine surface finishes and tight dimensional resistances, while turning is usually made use of to produce round components with accurate sizes. Milling and drilling operations are essential for forming and producing holes in fasteners, guaranteeing they satisfy specific specifications and function correctly.

Enhancing Speed and Efficiency

To optimize fastener manufacturing procedures, it is necessary to improve operations and execute reliable techniques that match accuracy machining methods. One vital technique for enhancing speed and efficiency is the application of lean production concepts. By decreasing waste and concentrating on constant renovation, lean practices assist maximize and remove traffic jams process. Additionally, spending in automation modern technologies can considerably increase manufacturing rate. Automated systems can take care of recurring jobs with precision and rate, permitting employees to concentrate on even more complex and value-added activities. Embracing Just-In-Time (JIT) stock administration can also enhance effectiveness by making sure that the appropriate materials are readily available at the best time, reducing excess stock and minimizing preparations. Furthermore, promoting a culture of cooperation and interaction amongst staff member can improve general performance by advertising transparency, problem-solving, and advancement. By integrating these techniques, producers can attain a balance in between speed and precision, eventually boosting useful reference their affordable side in the bolt market.

Quality Control Steps

Carrying out rigorous top quality control steps is critical in making certain the dependability and consistency of bolt products in the production procedure. Fasteners and Machining. Quality control actions encompass numerous stages, beginning from the option of raw products to the last evaluation of the finished fasteners. This includes evaluating factors such as material durability, toughness, and structure to guarantee that the bolts meet sector standards.

Normal calibration of equipment and equipment is vital to keep uniformity in production and make certain that bolts meet the needed tolerances. Implementing strict methods for identifying and resolving defects or non-conformities is vital in avoiding substandard items from going into the market. By developing a thorough quality assurance framework, makers can support the credibility of their brand and deliver fasteners that fulfill the highest criteria of performance and durability.

Final Thought

In the detailed realm of fasteners and machining, the pursuit for precision and speed is a continuous difficulty that demands precise attention to information and strategic planning. When it comes to bolts and machining applications, the product selection plays an important duty in figuring out the general strength, sturdiness, rust resistance, and compatibility with the desired environment. Accuracy machining includes numerous innovative techniques that make certain the tight resistances and requirements required for fasteners.In enhancement to CNC machining, various other precision methods like grinding, turning, milling, and drilling play important roles in bolt manufacturing.To optimize fastener production procedures, it is vital to streamline procedures and apply effective techniques that match accuracy machining techniques.